The original

Performance: The R 926 Compact combines the power and versatility of a standard machine with a smaller footprint of a short-tail excavator, making it an ideal solution for inner-city construction sites. The wide range of working equipment and options means that this machine can be configured for earthmoving, canal construction or demolition work of any kind.

Reliability: with over 50 years of experience in the development of crawler excavators, Liebherr offers its customers machines of the highest reliability. The high quality of the product is guaranteed at all stages, from design to final assembly. At the same time, the working conditions for the operator are always made safer. This recognized reliability is also reflected in Liebherr's numerous services, specially designed to support and satisfy our customers.

Comfort: The cab of the R 926 Compact is not only extremely comfortable and spacious, but it also offers an excellent view of the working environment and is also equipped with state-of-the-art technologies that allow the operator to exploit the full performance potential of this excavator in a very Pleasant working environment.

Cost-effectiveness: the new maintenance concept of the R 926 Compact helps to reduce downtime and thus increases productivity. In addition, the extremely intelligent energy management and automatic tool change enable operating costs to be reduced.

The 1:14.5 scale model

After more than 10 years of successfully introducing the Liebherr R956 and R946, we have ventured into a new ton class . Many product innovations from the larger models have been incorporated into the R926 Compact. Through the exclusive license from LIEBHERR, we have managed to develop a model that is even closer to the original than was previously possible.

In 2019, the time has come for us to launch the new R926 Compact as a model on the market. The crawler excavator is intricately detailed and the functions of the original are implemented in a new form of sensitivity and performance, as known from our R946/R956/R960 SME and our other models. Only the most suitable materials are used. The model is available as a finished model as well as a kit.

We would like to take this opportunity to thank LIEBHERR for their openness and trustful cooperation. We are very proud of this partnership!

Construction and materials used:

- Undercarriage (steel and brass, CNC turned, milled and laser cut)

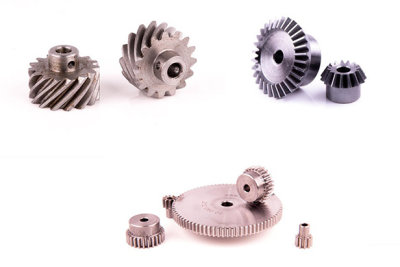

- Prestressed slewing ring with four-point support made of CNC milled steel; all gears made of C45 steel

- Hydraulic rotary joint for hydraulic auxiliary function in the undercarriage (blade)

- Superstructure plate made of 4mm steel with additional weights at the rear

- 3D printed plastic superstructure (uv-resistant and robust)

- Boom and stick made of solid 3D printed SLS parts and 5 axis CNC aluminum parts

- A-frame made of steel micro welded

- All bearing points equipped with plain bearings

- Bucket welded from steel with steel teeth in original look

- Chains in perfect detail

Technical data:

- Scale: 1:14,5

- Length undercarriage: 324 mm

- track width (outside): 206 mm

- Track width crawler track; 164 mm

- Maximum digging depth: 468 mm

- Height to cab roof: 211mm

- Width of upper carriage: 205 mm

- Weight of excavator: 14 kg +

Drive Technology:

- Crawler drive: Faulhaber industrial motors with precision planetary gearboxes in the side aisles, all shafts with ball bearings, all gears made of steel

- Chain tensioner made of steel and aluminum self-tightening

- Slewing gear: PREMACON DIRECT Drive, direct connection between slewing ring, slewing motor. Slew ring slewing shaft adjustable with slewing block.

Hydraulics

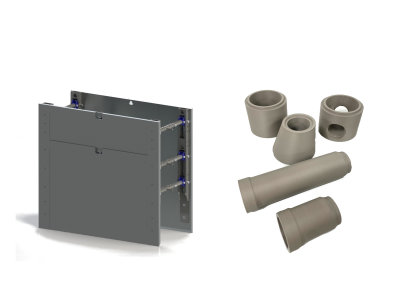

- The model hydraulics were taken from the large-scale R946/R956 models. A large-volume pump with standard-size valves is used.

- The scale appearance of the hydraulic cylinders and piping once again set the standard.

- Optimized pipe cross-sections for optimum use of hydraulic power

- PREMACON hydraulic valves NG 2.0 in industrial quality with outstanding fine controllability

- hard-piped cylinder lines

- hydraulic cylinders with bolted heads completely demountable, industrial seals with wiper

- hard-chrome plated piston rods, cast cylinder eyes (low internal friction thus more pressure is converted into working power)

- Large volume tank with special internal geometry to ensure oil delivery even at extreme lean angles; no foaming; no temperature problems

- Hydraulic filter integrated in the tank

- Working pressure approx. 26 bar

- Optional: bulldozer and support blade with hydraulic rotary feed-through and shut-off valve

Electronics

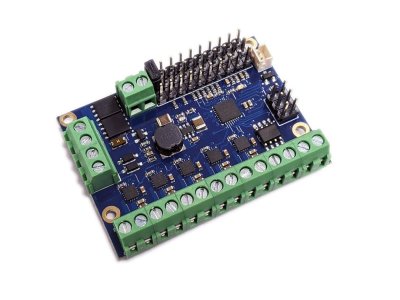

- Servonaut MFX controller for chain drive and slewing drive

- Industrial rotary feedthrough for endless turning of the upper carriage

- Special POWER LED's as headlights

- 4,5 A Power BEC

- HiTec brand servos for hydraulic valve control

- Operating voltage: 12 V Nimh or 3S Lipo cells

Required basic equipment for a functional model

- Basic kit

- Drive kit

- Hydraulic kit

- Electronics kit

Optional equipment / accessories (excerpt)

- Auxiliary hydraulics

- Support / dozer blade

- Quick coupler hydraulic

- Additional headlights

- Stone guard

- Heavy-duty chain deflector

- Likufix

- PREMACON sound module V2.0

- Paintwork / Assembly

- Attachments

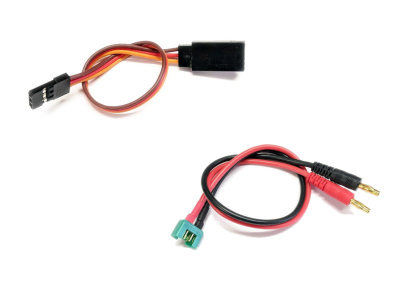

Required accessories:

- Remote control

- Battery

Pictures show the finished model with optional equipment. The basic kit is delivered unpainted and not assembled.