The original

With an optimal blend of productivity and precision, R956 crawler excavators enable you to work in a wide range of excavation or quarry applications. Thanks to their proven hydraulic concept and different operating modes, Liebherr excavators always adapt to your needs. Thanks to the equipment kinematics and the performance of the hydraulic system, R956 crawler excavators develop very high breakout and breakaway forces. The generously designed cylinders guarantee an increase in productivity even in hard material.

The 1:14.5 scale model

The crawler excavator is elaborately detailed and the functions of the original are implemented in a new level of sensitivity and performance. Only the most suitable materials are used and the model is available as a finished model as well as a kit.

Dimensions and weight:

- Length undercarriage: 398 mm

- Width of tracked undercarriage (outside): 265 mm

- track width track drive; 200 mm

- Height of crawler track: 85 mm

- Maximum digging depth: 540 mm

- Height to cab roof: 245 mm

- Width of upper carriage: 206 mm

- Weight of the excavator: 22 kg +

Structure and materials used

- Undercarriage HD steel and brass, CNC turned and milled undercarriage components

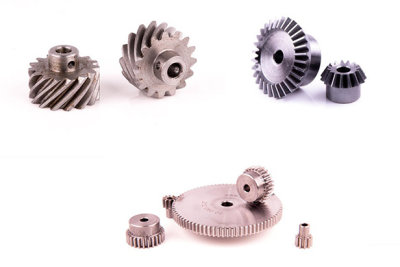

- preloaded slewing ring with four-point support made of steel, CNC milled, all gears made of steel C45

- Overcarriage plate made of 6mm steel (two 3mm plates bolted together)

- Overhead fairing made of 3D printed parts in finest detailing

- boom made of sheet steel and zinc die casting, various scale parts made of brass / zinc die casting

- Alloy boom, sandwich construction and zinc die-cast scale parts

- A-frame made of steel, micro-welded

- Continuous 8 mm bolts for all parts on the boom

- All bearing points fitted with bronze plain bearings

- Bucket micro-welded from steel teeth from brass / cast stainless steel

- Chains: Three-strand or two-strand chain links in perfect metal detailing

Equipment:

- Boom on steel plate with zinc die-cast scale parts.

- Stem made of aluminum sandwich construction

- Scale hard piping with option of auxiliary hydraulic functions

- All bearings with bushings

- Excavator throughout with 8mm bolts at all bearing locations

Undercarriage:

- Material: steel, aluminum, brass (CNC machined, laser cut or turned components).

- Cast original Liebherr Turas drive rim

- Absolutely original undercarriages with micro-welded chain guides and undercarriage components made of brass / die-cast zinc

- Three-steel or two-steel tracks (accessories) in perfect metal detailing

Turntable:

- Preloaded backlash-free slewing ring with PREMACON Direct Drive (see pictures).

- Pivot drive Direct Drive: direct connection of drive motor with attachment planetary gear to the slewing ring toothing without deflection (minimum backlash in the slewing drive, higher performance and more sensitive control)

Upper carriage:

- 6mm steel plate (2x3mm plates bolted together) as a solid base.

- Upper carriage in premium detailing (100% scale)

- Cab with all details as in the original: cupholder, driver's seat with armrests, Liebherrjoysticks, coolbox, radio, vents etc.

- Cab door can be opened

- A-frame made of steel, micro-welded

Drive technology undercarriage

- chain drive is provided by two independently controllable motors via bevel gears and roller chains on the Turas

- Motors: PREMIUM Faulhaber industrial motors with precision steel planetary gears installed in the side bays

- Multiple ball bearing mounted shafts and drive elements, all gears made of steel

- steel and aluminum self-tensioning chain tensioners

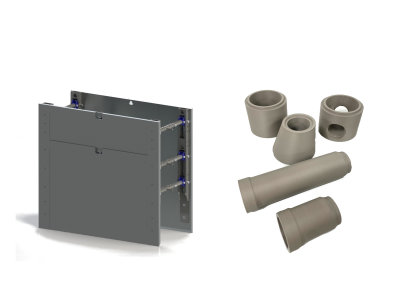

Hydraulic set

- Industrial hydraulic pump from JUNG Fluidtechnik in combination with Kampshoff/PREMACON Silent Drive. (quietest pump drive in the competition)

- PREMACON hydraulic valves version NG 2.0 with outstanding fine controllability. Adjustment is made via Hitec brand servos

- Multi-sealed, completely demountable hydraulic cylinders with hard-chrome plated piston rods

- Piston rods 8mm in diameter because of scale optics and for more efficient oil flow control on the piston side

- Large capacity tank approx. 350ml; special internal geometry to ensure oil flow even at lean angles

- No foaming no temperature problems due to Premacon passive cooling System

- oil filter in the tank as standard.

- Working pressure 24-25bar+.

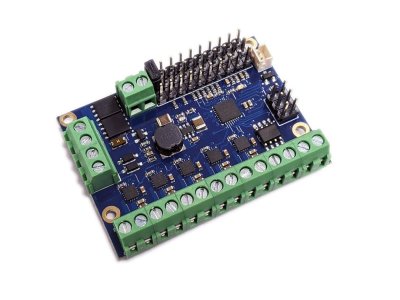

Electronics:

- Servonaut MFX controller for chain drive and slewing drive.

- Industrial rotary feedthrough for endless turning of the upper carriage

- Special POWER LED's as headlights

- Power BEC

- Electronic distributor with fuse and main switch

- Hitec brand servos for hydraulic valve control

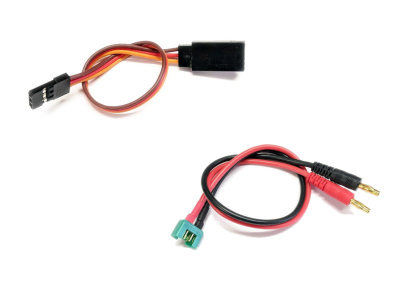

- Operating voltage: 12 V Nimh or 3S Lipo cells

Special equipment or accessories:

- Hydraulic quick coupler

- mechanical quick coupler

- additional hydraulics (2 additional hydraulic connections on the stick with supply and return incl. 2 additional hydraulic valves, piping and Oil Stop quick couplings)

- chain guide Heavy Duty (four additional chain guides at the rollers)

- Scale package: set of photo-etched parts for all ventilation grilles

- Special paint

- Stone guard for cabin complete (roof and windshield)

- Stone impact protection single either roof or front windshield

- light package: additional headlights on the boom and under the cabin

- two-link chain

- Sound module

- additional ballast in the undercarriage

Recommended remote controls:

- Computer remote control with at least 8 proportional channels.

- In conjunction with auxiliary hydraulics, 10 proportional channels are required.

- In connection with hydraulic quick coupler and auxiliary hydraulics 11 proportional channels are necessary.

- 4 proportional channels are additionally required to control the sound module.

Pictures show the finished model with optional equipment. The basic kit is delivered unpainted and not assembled.